I accept VadaTech copyright information.

Home

Products

Newsroom

By Function

|

I accept VadaTech copyright information.

Please enter your email registered at VadaTech and we will send you your password.

AArapidly changing market landscape requires VadaTech's customers to manage uncertainty, risk and evolving technologies, thus demanding a nimble response. We help our customers to meet the demands of their markets by using – wherever possible – open, standards-based hardware and software platforms.

An open standard means easy access to a definition of everything a vendor needs to know about building equipment and writing software that will work with compatible products from other vendors.

Users benefit because they are not beholden to a single supplier, as is often the case when proprietary technologies are used. With proprietary products, technology upgrades are often slow in coming. Users of open standards can pick and choose their vendors, who must continuously compete on both price and performance.

Our long experience with customers shows there are significant advantages to porting application boards and legacy systems into open, standards-based form factors. In fact, this has been one of our distinctive service offerings over the years.

One of the great values of an open standard is that it is not controlled by any single company, and the development and updating of these standards is controlled by a large group of interested parties working under the umbrella of an industry consortium using well defined and well tested processes.

With a focus based on open standards managed by the VITA and PICMG trade associations and the PCI Special Interest Group (PCI-SIG), VadaTech offers unmatched product selection and expertise, especially in the areas of data acquisition, signal processing, FPGA modules, rugged systems, and other cutting edge embedded technologies.

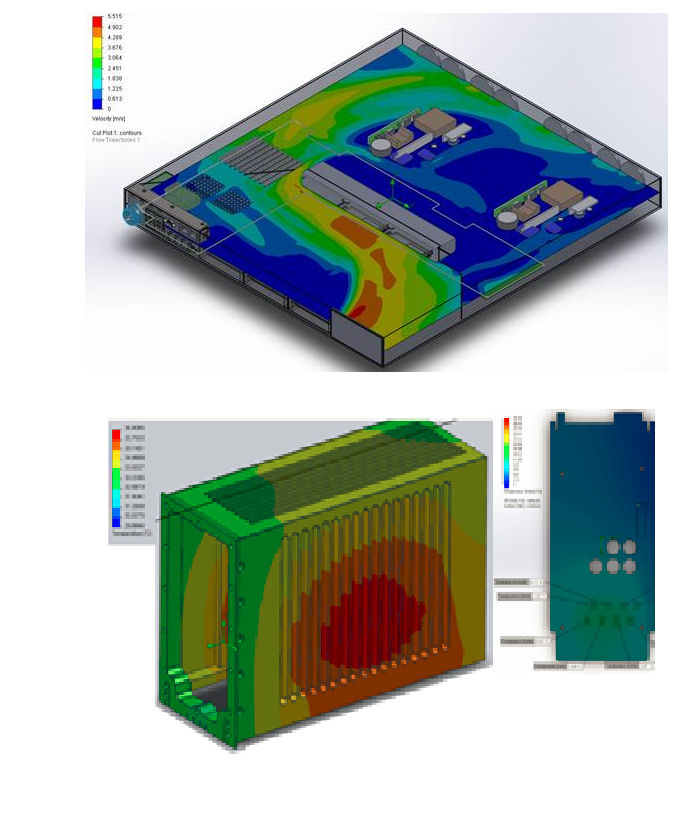

We understand that effective thermal management is an important system feature whether your application will operate in commercial or defense environments. Depending on the product type and target market, our design cycle can include airflow characterization (for modules) or MacroFlow CFD flow simulation for chassis or systems. We use an in-house environmental chamber to confirm the design characteristics of platform level solutions.

We understand that effective thermal management is an important system feature whether your application will operate in commercial or defense environments. Depending on the product type and target market, our design cycle can include airflow characterization (for modules) or MacroFlow CFD flow simulation for chassis or systems. We use an in-house environmental chamber to confirm the design characteristics of platform level solutions.

Many of our products are designed to AdvancedTCA and MicroTCA standards. This gives the benefit of a fully managed platform, with multiple temperature sensors on each line replaceable unit (LRU) and dynamic fan speed control. The user can set policies in the platform manager to determine how the system reacts to over-temperature conditions, and the architecture enables remote reporting of platform status as standard.

For mission-critical defense applications, VadaTech offers battle short override and cold start extensions to this standard capability, allowing prime contractors to configure a system for critical use cases.

We apply design validation techniques appropriate to the end user application and the class of product involved. Whether it’s a standard module- or chassis-level products, or we’re collaborating with you on a complete integrated platform, our validation and test methodology is rigorous and has been refined over many years. We will work with you to define system-level validation, identifying the process used to show line-by-line compliance with the specification.

For rugged products this will typically include mechanical (e.g. finite element analysis) and thermal (e.g. computational fluid dynamics) analysis. We have in-house facilities to confirm compliance with shock/vibration, thermal or humidity requirements. Using the same facilities, we can apply environmental stress screening (ESS) to enhance product reliability, as often defined in the supply contract.

For higher volume OEM customers, VadaTech offers the ability to pre-load customer application software and validate operation at the final product level, drop-shipping around the world if required.

An example of drop-ship provision is discussed here.